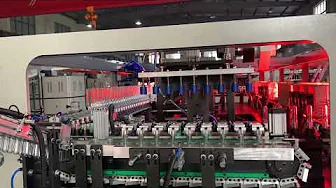

6 Cavities fully Automatic PET Bottle Blowing Machine

1.1 New Auto Preform Unscrambler System.

*Adopts one-way preform-feeding structure and preform-separating by servo motor structure which solve the preform block and abrasion problem.

*There are two photoelectric sensors to control preform-loading motor and preform-separating cylinder that will warn the operator to add the preforms into the hopper when lacks preform instead of stopping the machine.

1.2 New Heating System.

*Perfect heating system design decrease power consumption.

*Special oven design helps power saving and easy maintain.

*Each lamp position and temperature can be adjusted.

*Cycle air-cooling system keeps the oven temperature constantly.

1.3 The Application Of Servo System On Main Transmission.

The transmission adopts servomotor for positioning that can orientate the preform-heating base quickly, accurately and steadily when the machine starts and running.

1.4 Servo Technology Innovation On Clamping System & Stretching.

*Adopts servo motor to drive the two cranks to control the clamping system which can shorten the mold-clamping time and improve productivity, and also solve the swelling mold and big joint line problem with the effect of pressurize plate.

* Servo motor using for stretching to ensure the bottle blowing speed faster and more stable bottle quality.

Related News

What you should know before purchase blow molding machine?

The bottle blowing machine is mainly used to blow the preform into a finished bottle. There is no unified specification for domestic blow molding machines, and the technical level is also different, so what shoould customer pay attention to while they are going to purchase blow molding machine?